Why choose Glass Expansion?

For Quality, Reliability, and Innovation

You want the best performance your instrument can provide. You also want consistency, so that you can replace consumable parts such as nebulizers, spray chambers, and torches without having to spend time optimizing your instrument for the new parts.

We believe that exceptional product quality requires excellence in design, production, and service. While advanced production methods and high-quality finishes are important, outstanding design is essential. Without it, a product cannot reach its full potential.

Our ongoing investment in research and development—including the use of in-house ICP and ICP-MS instruments from a range of manufacturers - allows us to deliver innovative design solutions. These innovations ensure optimal performance, consistency, and reliability across all instrument platforms.

Glass Expansion has manufactured sample introduction components for ICP emission and mass spectrometers since the early 1980s. Today we support instruments from 16 manufacturers, providing sample introduction systems for over 50 different ICP and ICP-MS models. Many major ICP manufacturers supply our products as standard. Our products are widely used and embraced by recognized analysts in the ICP industry and are recognized as 'industry standard' products. Our intimate understanding of the relationship between the various sample introduction components, together with our ability and expertise in manufacturing high-quality nebulizers, spray chambers, torches, and other ICP components, means that we can offer you a complete solution to your ICP sample introduction needs.

Here are some examples of what our commitment to research has accomplished:

- Glass Expansion revolutionized spray chamber design by introducing cyclonic spray chambers. That's right, before the 'Tracey' cyclonic spray chamber, Scott-style spray chambers were the norm. The design of our cyclonic spray chambers helps you achieve sensitivity gains, reduced washout times, and reduced matrix effects not possible with other types of spray chambers.

- Our fully demountable torches, with all components being removable and replaceable, are also an industry first, enabling you to make operating and using torches more efficient and less expensive. With the high-precision ground torch base, you can replace any of the three individual tubes while maintaining accurate alignment and concentricity. All replacement components are so precisely manufactured that you don't need any further optimization after you've replaced a tube. Changing torch tubes is so quick and easy, reducing downtime and increasing instrument productivity.

- We manufacture nebulizers to operate optimally at the gas pressures and flow specified by the ICP instrument manufacturers. Instead of manufacturing nebulizers that operate within a certain gas pressure and flow range, we go the extra distance in our drive for quality. We manufacture our nebulizers according to your ICP specifications because we understand how critical these specifications can be. We also understand that your time is important and that you shouldn't have to waste it on recalibrating your instrument each time you change your nebulizer.

Reproducibility of analytical results in ICP analyses is of paramount importance. In an environment where a small change or inconsistency in a product or variable can result in a dramatic change in analytical results, design quality and reliability is essential. Glass Expansion has developed unique and proprietary manufacturing methods, which enable the production of components with the high mechanical strength and micron-level dimensional accuracy to satisfy the narrowest of analytical specifications, every time. Our products are recognized worldwide for their excellent precision, cost-effectiveness, and reproducibility of results.

This reproducibility provides you with the following benefits:

- Short-term background and RSD's are lower

- Long-term drift is lower

- Analytical result spread, measured for successive test batches of Glass Expansion components, is narrower

Our design and manufacturing processes ensure reliability in the performance of our products, which helps you minimize variables that can affect your analyses. Your needs are the crux of our product design, quality, reliability, and innovation. Some of our recent responses to your needs have led to the development of user-friendly solutions such as our quick-connect EzyFit and EzyLok fittings for nebulizers, GazFit connectors for torches, and EzyLok fittings for jacketed spray chamber coolant hoses. We pride ourselves on being attentive to your needs.

How is Glass Expansion Different?

Our products are designed by our experienced R&D team

- Well thought out

- Meticulously designed

- Precisely manufactured

We provide our customers with full technical support

- Experienced applications scientists

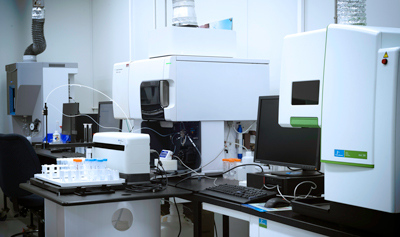

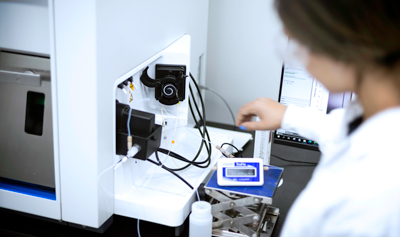

- Extensively equipped laboratory with 5 in-house ICP spectrometers.

At our corporate headquarters in Melbourne, Australia, our test laboratory is equipped with PerkinElmer Avio® 200, Agilent® 5900 SVDV, and Thermo Scientific™ PRO Duo ICP-OES instruments. In the case of ICP-MS, the laboratory is equipped with an Agilent® 7900 and a Thermo Scientific™ RQ. This allows us to do real-world testing of new products so there is no doubt they will perform optimally in your instrument.

Glass Expansion Trademarks*

Glass Expansion have been specializing in sample introduction components for ICPs since 1985. Many ICP vendors package GE parts as part of the standard configuration. As leading experts in ICP sample introduction components, we are dedicated to:

- Quality By Design

- Value

- Analytical Performance

- Better usability

Trademarks of Glass Expansion are as follows:

- Conikal

- SeaSpray

- MicroMist

- Slurry

- VeeSpray

- PolyCon

- U-Series

- UniFit

- OpalMist

- Tracey

- Cinnabar

- Twister

- Twinnabar

- ABC Torch

- GazFit

- Eluo

- Capricorn

- Helix CT

- Niagara

- Trident CT

- IsoMist

- IsoMist XR

- IsoMist MS

- TruFlo

- DuraMist

- Contour

- Direct Connect (DC)

- Nexus

- Guardian

- RotaValve

- HydraMist

- ConeGuard

- Jet Vortex Interface (JVI)

- PuraFlex

- D-Torch

- ConstantTorque

- EzyFit

- VitriCone

- Lotis

- E-Torch

- Glass Expansion

- Glass Expansion Logo